Dosing in pumps, chemistry, or medicine means adding the right amount of a substance at the right time. What is the purpose of dosing? Dosing helps avoid giving too little, which does not work, or too much, which can be wasteful or even harmful.

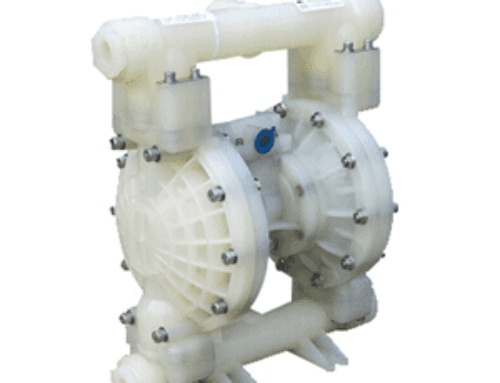

In industry, dosing pumps add exact amounts of chemicals like chlorine for water treatment, fertilizer for irrigation, or additives in food and medicine. This keeps processes safe and consistent.

In medicine, dosing makes sure patients get enough medicine to help them without causing harm. In agriculture, giving crops the right amount of nutrients helps them grow well and prevents damage to their roots.

The main goal of dosing is control. It keeps biological, industrial, and environmental systems working by adding substances in measured amounts instead of all at once. This balance helps make water safe, medicines work well, and factories run smoothly.

The Purposes of Dosing Across Industries

Dosing is used everywhere, but its purpose changes depending on whether it is for people, water, machines, or soil. Here is how dosing works in different areas:

1. Medical and Pharmaceutical Sector

In medicine, dosing is fundamentally about balancing healing and harm. Drugs must be given in just the right quantity so that they provide therapeutic benefit without slipping into toxicity.

A patient who receives too little medication will not recover, while a patient who receives too much risks severe side effects. Thus, doctors and pharmacists calculate doses based on factors such as body weight, metabolism, and the severity of the illness. Even vaccines rely on precise dosing to trigger an immune response without overwhelming the body.

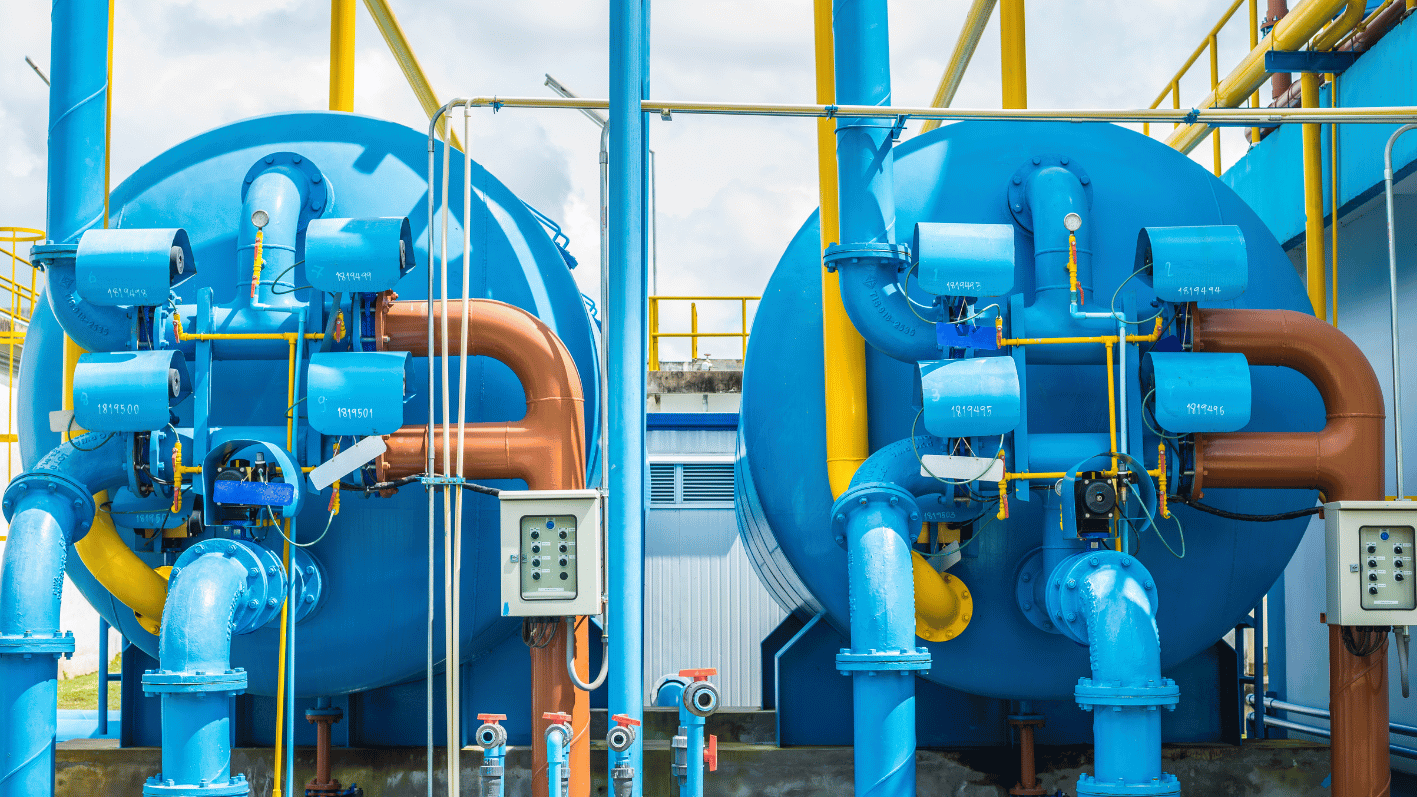

2. Water and Wastewater Treatment

In the world of water treatment, dosing is what keeps our taps safe. Chemicals such as chlorine, ozone, or pH adjusters are injected into municipal water supplies in controlled amounts.

If there is too little, harmful microbes or chemical imbalances persist; if there is too much, the water becomes unsafe to drink. Wastewater plants also depend on dosing to add coagulants that bind contaminants together, making them easier to remove. Accurate dosing ensures the end result meets health and environmental standards.

3. Agriculture and Irrigation

Agriculture uses dosing to ensure crops receive nutrients and protection in carefully measured amounts. Fertigation systems, which combine fertilizer with irrigation water, rely on dosing equipment to deliver just enough nutrition for plants to thrive.

Excessive fertilizer can burn roots and degrade soil quality, while insufficient fertilizer leads to stunted growth. The same principle applies to pesticides and herbicides: precision keeps pests under control without harming beneficial insects or creating chemical runoff that pollutes rivers and lakes.

4. Food and Beverage Industry

In food and beverage manufacturing, accurate dosing is essential for maintaining consistency, ensuring safety, and achieving optimal taste. When a soft drink is bottled, for example, the syrup and carbonated water must be mixed in exact proportions.

Even the smallest miscalculation changes the flavor profile. Preservatives, flavorings, and vitamins are also added using dosing systems to guarantee that each product meets safety regulations and consumer expectations. Without dosing, one bottle of juice might taste bland while the next could be overwhelmingly sweet.

5. Chemical and Industrial Manufacturing

In industrial settings, dosing ensures that complex chemical processes remain efficient and safe. For instance, petrochemical facilities use dosing to add corrosion inhibitors that protect pipelines from damage. Textile and paper factories use dyes and bleaching agents to dye and bleach materials, achieving uniform color and brightness.

If the chemicals are not dosed precisely, entire production runs may be wasted, machines can be damaged, or hazardous conditions may arise. Dosing keeps everything controlled and repeatable in environments where even small variations can have expensive consequences.

6. Energy and Power Generation

Energy production also relies heavily on dosing to maintain system performance. Boilers, turbines, and cooling towers are constantly exposed to heat, pressure, and flowing water, which can lead to scale buildup, microbial growth, or corrosion.

To prevent these problems, chemicals such as anti-scalants and biocides are dosed into water circuits. The purpose is to extend the lifespan of expensive equipment and maintain efficiency. Without this careful control, power plants would suffer frequent breakdowns and reduced output.

7. Cosmetics and Personal Care

In cosmetics, dosing determines whether a product is soothing or harmful. Ingredients like preservatives, fragrances, and active compounds must be added in strict proportions. Too little preservative and the product spoils; too much fragrance and the skin becomes irritated.

Regulations exist to limit the concentration of active chemicals such as salicylic acid in acne creams, and manufacturers use dosing systems to comply with these rules. Precision here ensures both consumer safety and consistent product quality.

8. Environmental Protection

Dosing is also a tool for protecting the environment. Industrial plants often produce effluents that are acidic, alkaline, or otherwise hazardous. Neutralizing agents are dosed into these effluents so that they can be safely discharged into rivers or oceans.

In air pollution control systems, chemicals are injected into scrubbers to capture harmful gases, such as sulfur dioxide, before they escape into the atmosphere. The goal in both cases is to prevent damage to ecosystems by restoring balance before pollutants spread.

So, what is the purpose of dosing? In every field, dosing means adding a substance carefully, in the right amount and at the right time, to get the results you want without causing problems. Whether in medicine, farming, industry, or protecting the environment, dosing helps keep things in balance.

Leave A Comment