Chemical dosing pumps are essential in industries that need precise chemical delivery. While standard pumps move large volumes, dosing pumps add small, measured amounts to specific systems.

This helps control processes, improve safety, and protect equipment in water treatment, agriculture, and pharmaceuticals. More than that, automation makes the process more reliable and reduces waste.

What is a Chemical Dosing Pump?

A chemical dosing pump is designed to inject precise amounts of a chemical into a fluid stream, tank, or system. It delivers small, controlled quantities at set rates and intervals. Thus, it is vital in industries where the right chemical balance ensures safety, efficiency, and product quality.

The working principle is straightforward: a dosing pump draws chemical solution into its chamber during the suction phase and pushes it into the target system during discharge, all at a controlled rate.

Modern pumps allow for manual or automatic flow control and can connect to sensors for real-time adjustments based on variables such as pH or concentration.

Chemical dosing pumps are widely used in water and wastewater treatment, where they add disinfectants like chlorine to make water safe.

In agriculture, they deliver fertilizers or pesticides through irrigation systems with accuracy that prevents waste and environmental harm.

While, in food and beverage plants, they help mix preservatives, colorings, or flavorings so that every product is consistent.

In industrial and energy sectors, they protect equipment by injecting corrosion inhibitors, biocides, or anti-scalants into cooling towers and pipelines.

In short, chemical dosing pumps automate chemical delivery to ensure safety, consistent products, and efficient operations in many industries.

Are Chemical Dosing Pumps Safe?

Chemical dosing pumps make handling chemicals safer by automating the process and reducing the need for manual contact. Their safety depends on using the right materials, proper installation, and regular maintenance. Therefore, good engineering and careful setup are key to safe operation.

From a materials standpoint, dosing pumps are constructed using corrosion-resistant components like PVDF, PTFE, or stainless steel. Safety features, including back-pressure valves, leak sensors, and overpressure protection, are integrated to contain chemicals and prevent system failure. Advanced units provide automated alarms and emergency shut-off in case of operational anomalies.

Operational safety depends on precise calibration, secure containment, and correct ancillary equipment selection, including chemical-resistant storage, sealed lines, and ventilation. For instance, chlorine dosing requires containment and venting to avoid hazardous exposure.

Operators using dosing pumps must wear personal protective equipment (PPE) including gloves, goggles, and sometimes respirators, depending on the chemical. Training is essential; untrained staff can cause leaks or mix incompatible chemicals.

Automated dosing pumps improve environmental safety. They reduce chemical waste and the risk of accidental overuse, which can harm equipment or ecosystems.

Chemical dosing pumps are safe when made from the right materials, maintained regularly, and used according to safety guidelines. They only work well if used properly.

Types of Chemical Dosing Pumps

Chemical dosing pumps come in several types, each designed to move and inject chemicals with precision but using different mechanisms that make them better suited for certain applications than others.

Choosing the right type depends on the industry, the chemical, and the required level of accuracy. The main types include:

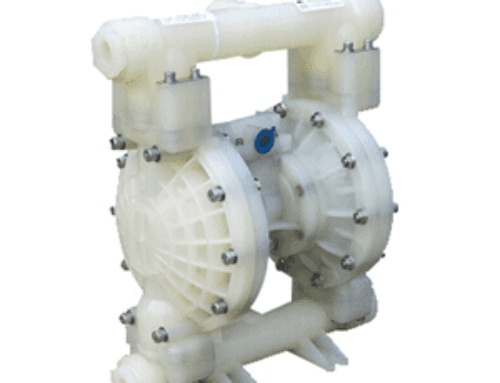

1. Diaphragm (Mechanical or Hydraulic) Dosing Pumps

Diaphragm pumps are the workhorses of dosing. They use a flexible diaphragm that moves back and forth to draw chemicals in during suction and push them out during discharge.

In mechanical diaphragm pumps, the diaphragm is moved directly by a crank or cam, while in hydraulic diaphragm pumps, hydraulic fluid moves the diaphragm indirectly.

These pumps are known for their accuracy and ability to handle aggressive or hazardous chemicals without leakage, since the liquid never touches moving metal parts. Therefore, they’re common in water treatment, oil and gas, and chemical plants.

2. Solenoid-Driven Dosing Pumps

Solenoid pumps use an electromagnetic solenoid coil to move the diaphragm back and forth. Because they are electronically controlled, they’re highly precise and easy to integrate with automation systems.

Their compact size makes them popular in laboratories, swimming pools, and small-scale water treatment facilities. So, they’re best for low- to medium-flow applications where fine dosing control is critical.

3. Peristaltic Dosing Pumps

Peristaltic pumps use a rotating roller mechanism that squeezes a flexible tube, pushing chemical liquid forward in a pulsing motion. The only part in contact with the chemical is the tubing, which makes them very versatile and safe for corrosive or viscous fluids.

They are easy to maintain since you just replace the tube when it wears out. Therefore, these pumps are widely used in the food and beverage sector, pharmaceuticals, and wastewater treatment.

4. Piston Dosing Pumps

Piston pumps use a piston moving inside a cylinder to displace fluid. They can generate very high pressures and are extremely accurate, which makes them suitable for demanding applications like oil refineries, power plants, or chemical processing. However, they are less ideal for highly corrosive or abrasive chemicals because the piston and seals are in direct contact with the liquid.

5. Stepper Motor-Driven Dosing Pumps

These are modern, digitally controlled pumps that use a stepper motor to drive the diaphragm with exceptional accuracy. Because stepper motors move in tiny incremental steps, the flow rate can be controlled very smoothly, without the pulsing effect of older pump designs.

They’re increasingly popular in advanced industrial settings that require smart control, like electronics manufacturing or precision agriculture.

The Best Pump for Chemical Dosing

No single pump is best for every chemical dosing job. The right pump depends on the chemical, required flow and pressure, and the application.

Each type has its advantages, so the best choice is the one that fits your needs safely and reliably. Here’s what works best in different industries:

1. Water and Wastewater Treatment

For municipal and industrial water treatment, diaphragm dosing pumps are usually the best choice. They provide high accuracy, can handle corrosive chemicals like chlorine or alum, and have leak-free designs that protect operators.

If the plant is automated, solenoid-driven diaphragm pumps are especially popular because they integrate smoothly with sensors and control systems.

2. Agriculture and Irrigation

In farming, peristaltic pumps and stepper-motor diaphragm pumps tend to be the best. Peristaltic pumps are simple to maintain and handle fertilizers or pesticides without contamination risks.

Stepper-motor pumps are gaining popularity because they allow precise fertigation.

3. Food and Beverage Industry

Here, the priority is hygiene and consistency. Peristaltic pumps are widely used because only the tubing touches the chemical or additive, which makes cleaning and replacement straightforward.

They also avoid contamination risks and are gentle enough for flavorings, colorings, and vitamins.

4. Pharmaceutical and Laboratory Settings

Accuracy and sterility dominate here, so solenoid pumps and peristaltic pumps are usually the best. Solenoid pumps offer ultra-precise control for micro-dosing, while peristaltic pumps ensure the fluid only touches the tubing, making it easy to keep sterile.

5. Heavy Industry, Oil, and Power Plants

For demanding, high-pressure applications such as chemical injection in refineries, boilers, or cooling towers, piston dosing pumps or hydraulic diaphragm pumps are the best. They can operate at high pressures and deliver exact volumes consistently, though they require careful maintenance.

6. Modern Smart Applications

If digital control and integration with IoT systems are required, the best choice is a stepper motor-driven dosing pump. They eliminate pulsing, allow remote monitoring, and can adjust chemical flow automatically based on sensor feedback, making them the cutting edge of dosing technology.

In summary, there is no single best pump for chemical dosing. The best option depends on the specific application. Generally:

- Diaphragm pumps = best all-rounders, safe for most chemicals.

- Peristaltic pumps = best for hygiene and harsh or viscous liquids.

- Piston pumps = best for high pressure and heavy industry.

- Solenoid pumps = best for small-scale, precise, automated dosing.

- Stepper-motor pumps = best for smart, digital dosing with fine control.

If you need help choosing a chemical dosing pump, contact WRS Dosing. We offer a wide range of pumps for many applications.

Leave A Comment