Chemical dosing pumps are the backbone of various industries, including water treatment plants, food processing facilities, oil refineries, and pharmaceutical laboratories. Their main task is simple yet critical: delivering exact amounts of chemicals into a process. However, because they often handle corrosive, toxic, or hazardous substances, one question always arises: Are chemical dosing pumps safe?

The answer is yes. When you select the right pump, install it correctly, and keep up with maintenance, chemical dosing pumps are one of the safest ways to handle and add chemicals. Let’s look at the features and best practices that make these pumps so reliable, even in tough conditions.

Built for Safety from the Ground Up

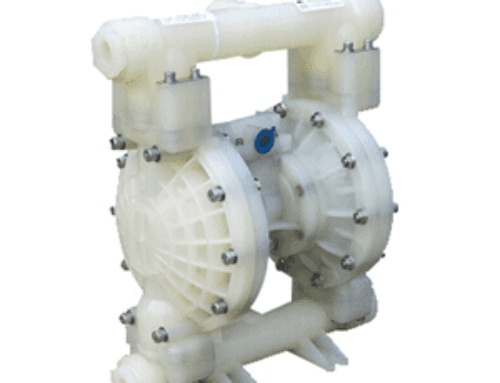

Chemical dosing pumps are built for accuracy and safety, unlike regular pumps. They use special mechanisms like diaphragms, pistons, or peristaltic systems to keep chemicals separate from moving parts. This design helps prevent leaks and reduces wear, which is especially important when handling dangerous materials.

Most modern pumps use corrosion-resistant materials such as PVDF, PTFE, or stainless steel (SS316). These materials withstand aggressive chemicals, such as acids, alkalis, and solvents, without breaking down. By resisting corrosion, pumps not only protect workers but also extend their own lifespans, reducing the chance of accidents caused by worn-out equipment.

Precision Reduces Risk

A major safety benefit of dosing pumps is their accuracy. Too much chemical can harm equipment or cause unsafe reactions, while too little might not remove dangerous contaminants. Accurate dosing keeps everything safe and working as it should.

Dosing pumps deliver the same precise amount every time, which helps avoid mistakes and keeps processes safe. For example, in water treatment, a dosing pump adds just the right amount of chlorine to disinfect water without making harmful byproducts.

Advanced Safety Features

Modern chemical dosing pumps are more than mechanical devices. They come equipped with built-in safety systems designed to prevent accidents before they happen. Common features include:

- Overpressure protection prevents damage to pipes or equipment when pressure exceeds a safe level.

- Dry-run protection: Stops the pump when the chemical tank is empty, preventing wear and overheating.

- Leak detection sensors: Alert operators immediately if a seal or diaphragm begins to fail.

- Flow verification: Confirms that the correct amount of chemical is being delivered in real time.

These features make dosing pumps much safer than handling chemicals by hand or using less precise pumps. Automatic systems help prevent problems like too much pressure, running dry, leaks, and dosing mistakes.

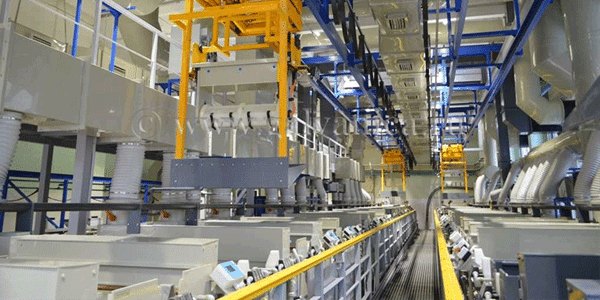

Integration with Automation Systems

Automation also improves safety. Many dosing pumps connect to control systems like SCADA, so operators can monitor and adjust chemical dosing from a distance. This means less direct contact with dangerous chemicals.

Because automation reduces the need for hands-on work, it lowers the risk of mistakes and accidents. It also keeps dosing safe and steady, even in busy industrial settings.

Best Practices for Safe Operation

While dosing pumps are inherently safe, their effectiveness depends on proper use and maintenance. Here are the key best practices that ensure maximum safety:

- Correct Pump Selection: Always choose a pump built with materials compatible with the chemicals you’re using. Using the wrong material can lead to rapid corrosion and leaks.

- Proper Installation: Pumps should be installed with appropriate safety accessories such as backpressure valves, pulsation dampeners, and safety relief systems.

- Regular Maintenance: Like any machine, dosing pumps require inspection and servicing. Replacing diaphragms, tubing, and seals on schedule prevents unexpected failures.

- Operator Training: Workers should be trained not only on how to operate the pumps but also on safety procedures in the event of alarms or leaks.

When these practices are followed, the risk of chemical exposure or accidents is extremely low. The primary advantage is that these pumps, when used properly, provide consistent protection for both people and processes.

A Safer Alternative to Manual Handling

The biggest reason dosing pumps are safe is that they replace manual chemical handling. Without pumps, workers would need to measure and mix chemicals themselves. Automation keeps people away from dangerous substances, making work safer for everyone and better for the environment.

So, are chemical dosing pumps safe? Yes. When the right equipment and practices are in place, these pumps provide unmatched safety for chemical handling. Compared to manual or less specialized pumps, dosing systems significantly reduce the risk to workers, processes, and the environment. Compared to manual or less specialized pumps, dosing systems significantly reduce the risk to workers, processes, and the environment.

Leave A Comment