A diaphragm pump is a highly versatile and reliable type of positive displacement pump used in many industries. Its simple design allows it to move fluids effectively, even when they are corrosive, thick, or contain particles. In this article, we explain how diaphragm pumps work, the main types available, and their importance in various industrial applications.

How a Diaphragm Pump Works

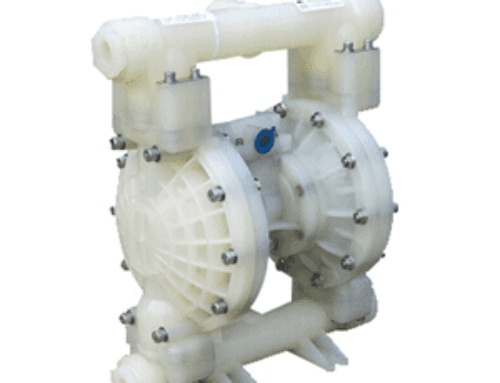

Diaphragm pumps have a flexible membrane known as the diaphragm, typically made of rubber, PTFE, or other chemically resistant materials. The diaphragm oscillates to draw in and discharge process fluid.

As the diaphragm moves backward, it creates a vacuum and opens the inlet valve, drawing process fluid into the chamber. When the diaphragm moves forward, it pressurizes the fluid, closes the inlet valve, opens the outlet valve, and transfers the fluid through the discharge port.

This process repeats, producing a pulsed, reliable flow. Only the diaphragm and valves contact the process fluid, making the pump ideal for handling aggressive or sensitive chemicals.

Because it operates on a positive displacement principle, a diaphragm pump can handle a wide range of fluid viscosities, from thin solvents to thick slurries. It is also self-priming and capable of running dry for short periods without damage, which is an advantage over many centrifugal pumps.

Main Types of Diaphragm Pumps

While all diaphragm pumps work on the same basic principle, they use different power sources. The two most common types are Air-Operated Double Diaphragm (AODD) pumps and Motor-Driven Mechanical Diaphragm pumps. Each type has its own uses and benefits.

1. Air-Operated Double Diaphragm (AODD) Pump

An AODD pump runs on compressed air. It has two diaphragms linked by a shaft. When air pushes on one side, it moves one diaphragm forward to pump out fluid and pulls the other back to fill the other chamber. The air switches sides to keep the pump working in a steady cycle.

Industries use this pump when handling safe chemicals or flammable materials, as it does not use electricity. Without electrical components, AODD pumps are safe in explosive or hazardous environments such as chemical plants, oil refineries, and mines.

Advantages of AODD Pumps:

- Can handle solids and slurries without clogging.

- Capable of dry running without damage.

- Suitable for viscous and abrasive fluids.

- Portable and easy to maintain.

- Variable flow rate controlled by air pressure.

Typical Applications:

- Chemical transfer and mixing.

- Paint, ink, and pigment circulation.

- Wastewater treatment and sludge handling.

- Food and beverage processing (using sanitary materials).

- Oil and gas operations where electrical use is restricted.

2. Motor-Driven Mechanical Diaphragm Pump

A motor-driven diaphragm pump uses an electric motor to move a cam or crank, which makes the diaphragm move back and forth. This setup allows for very precise control of the flow, making these pumps a good choice for metering and dosing fluids.

You can adjust the diaphragm’s stroke length and speed mechanically or electronically to control the amount of pumped liquid. Such precision is crucial in industries needing accurate chemical dosing for process quality and safety.

Advantages of Motor-Driven Diaphragm Pumps:

- Accurate and repeatable flow rate.

- Suitable for continuous operation.

- Capable of handling corrosive fluids with compatible materials (e.g., PTFE, PVDF, SS316).

- Requires no compressed air system, reducing operating costs.

- Easily integrates with control systems via analog or digital signals.

Typical Applications:

- Water and wastewater treatment (chlorine or coagulant dosing).

- Petrochemical and refinery dosing systems.

- Agricultural fertilization and irrigation control.

- Food and pharmaceutical ingredient metering.

- Power generation cooling and boiler water treatment.

Construction and Materials

The performance and lifespan of a diaphragm pump depend on the materials used for the diaphragm, valves, and pump head. Common materials include:

- PTFE (Teflon): Excellent chemical resistance, suitable for aggressive acids or solvents.

- EPDM and NBR: Flexible materials for general-purpose and oil-based fluids.

- PVDF and PP: Lightweight plastics with good corrosion resistance, often used in chemical plants.

- SS316 Stainless Steel: Resistant to corrosion and temperature, suitable for hygienic or high-pressure environments.

Choosing the right materials makes sure the pump works well with the fluid being moved. For example, use a PVDF head with a PTFE diaphragm for acids, and pick stainless steel for food or pharmaceutical applications.

WRS Dosing Provides All Types of Diaphragm Pumps

WRS Dosing makes precision dosing pumps for both industrial and commercial use. The company focuses on AODD and motor-driven diaphragm pumps, which are built for accuracy, long life, and chemical resistance. Each pump is designed to meet the needs of tough jobs in water treatment, petrochemicals, food and beverage, agriculture, and pharmaceuticals.

Each WRS diaphragm pump is designed for leak-free performance and long life. The materials ensure compatibility with many fluids, from acids to slurries and delicate chemicals.

WRS Dosing also provides technical support to help clients pick the best diaphragm pump for their needs. Their engineering team can advise on pump size, control options, and system setup. With dependable service, WRS Dosing helps companies boost efficiency, safety, and accuracy in their operations.

Leave A Comment