If you run a water treatment plant, make pharmaceuticals, or oversee agricultural irrigation, choosing the right dosing system helps everything run smoothly and prevents expensive mistakes. Dosing pumps stand out for their accuracy, safety, and cost savings. Here are 10 dosing pump advantages!

1. Accurate and Consistent Chemical Delivery

Dosing pumps deliver fluids with high precision. Unlike standard pumps that fluctuate in volume, dosing pumps maintain a consistent output over extended periods of operation. This keeps processes stable and predictable.

Accurate dosing reduces waste and minimizes the risk of costly rework. It also ensures compliance with industry standards, particularly in sensitive sectors like pharmaceuticals and food production. For companies seeking to safeguard both product quality and reputation, dosing pumps offer peace of mind.

2. Wide Range of Applications

Dosing pumps are versatile and work well in many industries. They perform reliably in places like municipal water treatment plants and biotech labs, handling different environments without losing efficiency. This flexibility makes them a practical solution for chemical dosing needs.

In agriculture, they help farmers apply fertilizers and pesticides precisely, preventing soil damage and reducing costs. In the food industry, they ensure consistent flavor profiles and safe levels of preservatives. No matter the sector, dosing pumps serve as the backbone of controlled liquid handling.

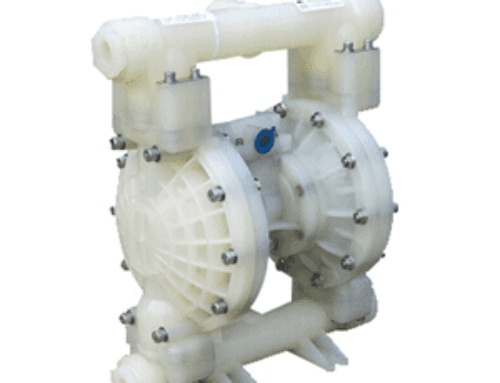

3. Compatibility with Harsh Chemicals

Dosing pumps are made with materials like PVDF, PTFE, and stainless steel, so they can handle harsh chemicals. This means businesses can use them with many different liquids without worry.

Because these pumps resist corrosion, they help prevent leaks and accidents, and they last longer. This leads to lower maintenance costs. For facilities that handle dangerous materials, this reliability means better safety and savings.

4. Energy Efficiency

Dosing pumps use much less power than traditional pumps. They work in short, controlled bursts instead of running all the time at high power. This makes them a more energy-efficient choice for companies looking to cut energy costs.

Energy efficiency is crucial in large operations where pumps operate continuously. Small power savings per unit can add up significantly across a facility, supporting both cost reductions and sustainability goals.

5. Easy Integration with Automation Systems

Modern dosing pumps are designed for today’s digital systems. They include features like RS-485 communication and 4-20 mA signals, so they connect easily with SCADA and other automation tools. Operators can monitor and control the pumps from a distance.

Connecting pumps to automation systems makes operations more efficient and reduces the need for manual checks. It also helps prevent mistakes, keeping dosing accurate even in large setups. Companies that want to stay up to date benefit from pumps that work with Industry 4.0 standards.

6. Safety Features to Protect Your Operations

Dosing pumps are designed for safety and efficiency. They have alarms that warn about overpressure, dry running, or empty tanks, so operators can fix problems early. Leak detection also helps protect workers and equipment.

These features are crucial when handling hazardous chemicals. By preventing accidents, pumps enable companies to comply with safety regulations and minimize downtime, ultimately leading to increased productivity and efficiency.

7. Reduced Risk of Contamination

In industries where purity is critical, contamination can’t be tolerated. Peristaltic dosing pumps, for example, ensure that liquids only come into contact with the tubing, thereby preventing exposure to the pump mechanism. This design virtually eliminates the risk of cross-contamination.

For food and pharmaceutical sectors, this capability is essential to uphold hygiene and pass audits. Customers benefit with safer, high-quality products, reinforcing brand trust.

8. Flexibility in Flow and Pressure Control

Dosing pumps can handle different flow requirements. Their adjustable settings let them meet exact needs in labs and industrial sites.

For example, the WRS Dosing Eignal Series EMG Model can deliver between 15 and 150 liters per hour at pressures from 10 to 4 bar. This flexibility means one pump can handle many different tasks, so you need fewer types of pumps.

9. Cost Savings Over Time

Dosing pumps may cost more at first, but they save money over time. Their accuracy cuts down on chemical waste, which lowers costs for supplies. Their strong build also means less maintenance and fewer replacements.

Lower downtime means increased productivity and smooth operations. In industries that use costly chemicals, reducing waste can quickly offset the initial investment. Dosing pumps ultimately provide operational and financial efficiency.

10. Future-Proof with Smart Technology

Fluid handling is becoming more digital, and dosing pumps are leading the way. Many models now have IoT sensors, data monitoring, and alerts for maintenance. These features give operators better information about how the pumps are working.

Predictive data helps spot problems early and prevent breakdowns. With cloud integration, companies can monitor pumps in real time from anywhere, making it easier to move toward fully automated operations.

Why Companies Choose WRS Dosing

WRS Dosing is a top choice among many brands, especially with its Eignal Series EMG Model. This pump offers reliable mechanical diaphragms and smart digital controls, making it a leader in industrial dosing. With flow rates up to 150 liters per hour and advanced alarms, WRS pumps are built for tough jobs.

Businesses in petroleum, agriculture, pharmaceuticals, and food trust WRS for its mix of value and innovation. WRS includes modern connectivity features as standard, not as extras. For companies that want both precision and durability, WRS is the top pick.

Dosing pumps advantages extend far beyond basic chemical delivery. They improve accuracy, save energy, protect workers, and reduce costs—while also aligning with the future of digital automation. No other type of pump delivers the same balance of safety, efficiency, and adaptability.

Leave A Comment