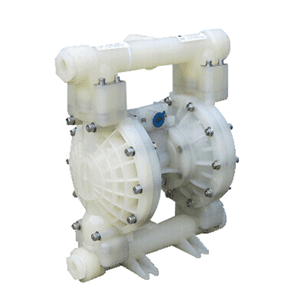

A diaphragm pump is one of the most reliable and versatile types of positive displacement pumps used in modern industries. It is designed to move liquids through the controlled flexing of a diaphragm, creating alternating suction and discharge actions. But, how do diaphragm pumps work?

Understanding the Basic Principle

The working concept of a diaphragm pump revolves around a flexible membrane called the diaphragm. This diaphragm is made from durable materials such as rubber, PTFE, or other elastomers that can withstand repeated motion and chemical exposure. The diaphragm divides the pump chamber into two parts: one for the liquid being pumped and one for the driving mechanism.

When the diaphragm moves backward, it expands the liquid chamber and creates a vacuum. This vacuum causes the inlet check valve to open, allowing fluid to enter the chamber. When the diaphragm then moves forward, it compresses the liquid, closing the inlet valve and opening the outlet valve. The fluid is pushed out of the chamber toward the discharge line.

This alternating movement—suction followed by discharge—forms a continuous pumping cycle. Because of its sealed design, the fluid never touches the mechanical parts of the pump, making it an excellent choice for hazardous, corrosive, or sterile applications.

Air-Operated and Motor-Driven Designs

Although the principle is the same, diaphragm pumps can be powered in different ways depending on their intended use.

The Air-Operated Double Diaphragm (AODD) pump uses compressed air as its power source. Inside the pump are two diaphragms connected by a shared shaft. When air pressure is applied to one side, it pushes one diaphragm forward (discharging liquid) while pulling the other backward (drawing in liquid). The air alternates between the two sides, allowing the pump to operate smoothly without the need for electricity. AODD pumps are widely used in industries where safety is critical, such as chemical processing, mining, and oil refining.

The Motor-Driven Mechanical Diaphragm pump operates with an electric motor and crank mechanism. The motor converts rotational motion into linear motion, which pushes and pulls the diaphragm. This design allows for precise control of flow rate and stroke length, making it ideal for dosing and metering applications such as water treatment, pharmaceuticals, and agriculture.

The Role of Check Valves

An essential part of a diaphragm pump’s design is its check valve system. Each pump chamber has an inlet valve and an outlet valve that open and close automatically in response to pressure changes.

When the diaphragm retracts, the inlet valve opens to let liquid in, while the outlet valve stays closed. When the diaphragm moves forward, the inlet valve closes, and the outlet valve opens, allowing liquid to exit. These one-way valves prevent backflow and ensure consistent, unidirectional movement of the fluid.

Why Diaphragm Pumps Are Reliable

The design of a diaphragm pump offers several advantages that make it a preferred choice across multiple industries. Because the pumped liquid is completely separated from the driving mechanism, the pump provides leak-free operation, which is essential for handling hazardous chemicals or sterile substances. It is also self-priming, meaning it can draw fluid from below the pump level without external assistance.

In addition, diaphragm pumps can run dry without damage, unlike many other pump types. This makes them suitable for operations where fluid supply may fluctuate. Their ability to handle corrosive, abrasive, or viscous liquids also gives them a clear advantage in demanding environments.

So, how do diaphragm pumps work? Diaphragm pumps work by alternately expanding and compressing a sealed chamber through the movement of a flexible diaphragm. This mechanism, supported by check valves, creates controlled suction and discharge cycles that move liquid efficiently and safely.

Leave A Comment