In today’s fast-paced industrial landscape, maximizing efficiency is essential for success. Choosing the right dosing pump can play a pivotal role in achieving this goal, but with the array of options available, the decision can feel daunting. Whether you’re managing a chemical plant, a water treatment facility, or a food processing operation, finding the perfect pump tailored to your specific needs is crucial. This ultimate guide will navigate you through the complexities of dosing pump selection, ensuring that you not only optimize resource use but also enhance your operational performance. From understanding pump types and flow rates to assessing compatibility with different substances, we’ll equip you with the knowledge to make informed decisions. Join us as we delve into the world of dosing pumps, where precision meets efficiency, and set your operations on the path to success. Let’s ensure every drop counts!

Understanding Dosing Pumps: An Overview

Dosing pumps are precision instruments used to deliver precise amounts of liquids into a system. These pumps play a crucial role in various industries, ensuring that chemicals, additives, or other substances are introduced at the right time and in the correct proportions. The primary function of a dosing pump is to control the flow rate and volume of liquid, making it indispensable in processes where accuracy is paramount.

The operation of dosing pumps is typically based on a positive displacement mechanism, which ensures consistent flow rates regardless of pressure changes in the system. This feature is particularly beneficial in applications where maintaining a steady concentration of a substance is critical. Dosing pumps are designed to handle a wide range of liquids, from aggressive chemicals to viscous fluids, highlighting their versatility and importance in industrial applications.

Understanding the basics of how dosing pumps work and their role in various processes is the first step in choosing the right pump for your needs. By familiarizing yourself with the fundamental principles of dosing pumps, you can make more informed decisions and enhance the efficiency and reliability of your operations.

Key Applications of Dosing Pumps

Dosing pumps are utilized across several industries, each with specific requirements and challenges. In the chemical industry, dosing pumps are essential for the accurate introduction of chemicals into processes such as water treatment, where precise dosing is crucial to ensure the correct chemical balance. Similarly, in the pharmaceutical industry, dosing pumps are used to dispense precise amounts of active ingredients, ensuring consistent product quality and efficacy.

In water treatment facilities, dosing pumps play a vital role in maintaining water quality by accurately introducing disinfectants, coagulants, and other treatment chemicals. These pumps help in achieving regulatory compliance and safeguarding public health by ensuring that treated water meets the required standards. Additionally, dosing pumps are used in agriculture for the precise application of fertilizers and pesticides, optimizing crop yields and reducing environmental impact.

The food and beverage industry also relies heavily on dosing pumps for the accurate addition of flavors, colors, and preservatives. This ensures product consistency and quality, which are essential for consumer satisfaction and brand reputation. By understanding the diverse applications of dosing pumps, you can appreciate their importance in various sectors and the need for selecting the right pump for each specific application.

Types of Dosing Pumps: A Comparative Analysis

When it comes to selecting a dosing pump, it’s crucial to understand the different types available and their respective advantages and disadvantages. The main types of dosing pumps include diaphragm pumps, peristaltic pumps, piston pumps, and electromagnetic pumps. Each type has unique characteristics that make them suitable for specific applications.

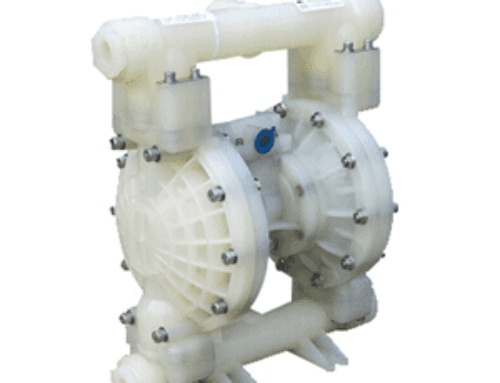

Diaphragm pumps are widely used due to their robustness and ability to handle a variety of liquids, including corrosive and viscous substances. These pumps use a diaphragm to create a vacuum, drawing liquid into the chamber and then expelling it at a controlled rate. Diaphragm pumps are known for their reliability and precise dosing capabilities, making them ideal for applications requiring high accuracy.

Peristaltic pumps, on the other hand, operate by squeezing a flexible tube to move the liquid. This design minimizes the risk of contamination since the liquid only comes into contact with the tubing. Peristaltic pumps are particularly suitable for handling shear-sensitive fluids and are often used in the pharmaceutical and food industries. However, they may have lower flow rates compared to other types of dosing pumps.

Piston pumps use a piston to displace liquid, offering high pressure and precise control. These pumps are suitable for applications requiring high accuracy and the ability to handle a wide range of viscosities. However, piston pumps may require more maintenance due to their mechanical complexity. Electromagnetic pumps, also known as solenoid pumps, use an electromagnetic coil to drive the diaphragm or piston. These pumps are known for their simplicity, reliability, and ease of maintenance, making them a popular choice for various applications.

Factors to Consider When Choosing a Dosing Pump

Selecting the right dosing pump involves evaluating several factors to ensure it meets your specific requirements. One of the primary considerations is the chemical compatibility of the pump materials with the liquids being handled. Different pumps are constructed from various materials, each offering resistance to specific chemicals. Ensuring material compatibility is crucial to prevent corrosion and extend the pump’s lifespan.

Another critical factor is the flow rate and pressure capabilities of the pump. Depending on your application, you may require a pump that can deliver liquids at high pressures or with precise flow rates. It’s essential to match the pump’s specifications with your process requirements to achieve optimal performance and efficiency. Additionally, consider the viscosity of the liquids being pumped, as this can affect the pump’s performance and suitability for your application.

Energy efficiency and cost considerations are also important when choosing a dosing pump. Look for pumps that offer high efficiency and low energy consumption to reduce operational costs. While the initial purchase price is a significant factor, consider the total cost of ownership, including maintenance, repairs, and energy consumption. By evaluating these factors, you can select a dosing pump that meets your needs while optimizing resource use and minimizing costs.

The Importance of Pump Capacity and Flow Rate

Pump capacity and flow rate are critical factors in ensuring the efficiency and effectiveness of your dosing system. The capacity of a pump refers to the maximum volume of liquid it can deliver within a specific time frame, while the flow rate indicates the speed at which the liquid is dispensed. Choosing a pump with the appropriate capacity and flow rate is essential to meet the demands of your application.

For applications requiring high precision, such as in the pharmaceutical or food industries, it’s crucial to select a pump that can deliver consistent and accurate flow rates. Variations in flow rate can lead to inconsistencies in the final product, affecting quality and compliance with regulatory standards. Therefore, it’s essential to choose a pump with precise control capabilities to ensure uniformity and reliability.

In addition to accuracy, consider the scalability of the pump’s capacity. If your operations are expected to grow or if you anticipate changes in process requirements, selecting a pump with adjustable capacity and flow rate can provide flexibility and future-proof your investment. By carefully evaluating pump capacity and flow rate, you can enhance the efficiency and performance of your dosing system.

Material Compatibility: Ensuring Chemical Resistance

Material compatibility is a crucial consideration when selecting a dosing pump, as it directly impacts the pump’s durability and performance. Different liquids have varying chemical properties, and using a pump constructed from incompatible materials can lead to corrosion, degradation, and eventual failure. Therefore, it’s essential to choose a pump made from materials that can withstand the specific chemicals used in your application.

Common materials used in dosing pumps include stainless steel, plastic, and elastomers. Stainless steel is known for its resistance to corrosion and high temperatures, making it suitable for handling aggressive chemicals and high-pressure applications. Plastic materials, such as PVC and PTFE, offer excellent chemical resistance and are often used in applications involving acids and bases. Elastomers, such as EPDM and Viton, provide flexibility and resistance to a wide range of chemicals, making them ideal for sealing and gasket applications.

When selecting a dosing pump, consult the manufacturer’s compatibility charts and guidelines to ensure the materials used in the pump are suitable for your specific chemicals. Additionally, consider the operating conditions, such as temperature and pressure, as these factors can also affect material compatibility. By ensuring chemical resistance, you can extend the lifespan of your pump and maintain consistent performance.

Energy Efficiency and Cost Considerations

Energy efficiency is a critical factor in reducing operational costs and minimizing the environmental impact of your dosing system. Selecting a dosing pump that offers high efficiency can lead to significant energy savings over the pump’s lifetime. Look for pumps with advanced technologies, such as variable frequency drives (VFDs), which allow for precise control of the pump’s speed and reduce energy consumption.

In addition to energy efficiency, consider the overall cost of ownership when selecting a dosing pump. While the initial purchase price is an important factor, it’s essential to evaluate the long-term costs associated with maintenance, repairs, and energy consumption. Pumps with lower energy consumption and minimal maintenance requirements can lead to substantial cost savings over time.

Another cost consideration is the pump’s reliability and longevity. Investing in a high-quality pump from a reputable manufacturer can reduce the frequency of repairs and replacements, further lowering operational costs. By taking a comprehensive approach to energy efficiency and cost considerations, you can select a dosing pump that meets your needs while optimizing resource use and minimizing expenses.

Maintenance and Longevity of Dosing Pumps

Regular maintenance is essential to ensure the longevity and optimal performance of dosing pumps. Implementing a proactive maintenance schedule can help identify and address potential issues before they lead to pump failure or process disruptions. Common maintenance tasks include inspecting and cleaning pump components, checking for wear and tear, and replacing worn parts as needed.

One of the key aspects of maintaining dosing pumps is monitoring the condition of the pump’s diaphragm, seals, and valves. These components are subject to wear and can affect the pump’s performance if not regularly inspected and replaced. Additionally, ensure that the pump’s motor and drive system are in good working condition, as any issues with these components can lead to decreased efficiency and increased energy consumption.

It’s also important to follow the manufacturer’s maintenance guidelines and recommendations to ensure the pump operates within its specified parameters. By maintaining your dosing pump and addressing any issues promptly, you can extend its lifespan, reduce downtime, and ensure consistent performance. Regular maintenance not only enhances the reliability of your dosing system but also contributes to overall operational efficiency.

Top Brands and Models in the Market

When selecting a dosing pump, it’s essential to consider reputable brands and models known for their reliability, performance, and innovation. Several manufacturers have established themselves as leaders in the dosing pump industry, offering a wide range of pumps tailored to various applications and requirements.

One of the top brands in the market is wrsdosing, known for its high-quality pumps and advanced technologies. wrsdosing dosing pumps are designed for precision and reliability, making them suitable for a wide range of industries, including water treatment, chemical processing, and food and beverage. The wrsdosing smart system pump, for example, offers advanced features such as flow control, integrated diagnostics, and a user-friendly interface.

Another leading manufacturer is ProMinent, which offers a comprehensive range of dosing pumps known for their accuracy and durability. ProMinent’s gamma/ X pump is a popular choice for various applications, featuring intelligent control technology, robust construction, and a wide range of material options to ensure chemical compatibility. Additionally, the company’s extensive support and service network provide added assurance for users.

Other notable brands include Watson-Marlow, known for its innovative peristaltic pumps, and Milton Roy, which offers a wide range of diaphragm and piston pumps. When selecting a dosing pump, consider the reputation and track record of the manufacturer, as well as the specific features and capabilities of the pump model. By choosing a reliable brand and model, you can ensure the long-term performance and efficiency of your dosing system.

Conclusion: Making an Informed Decision

Choosing the right dosing pump is a critical decision that can significantly impact the efficiency and effectiveness of your operations. By understanding the various types of dosing pumps, their key applications, and the factors to consider when selecting a pump, you can make an informed decision that meets your specific needs. Consider the importance of pump capacity and flow rate, material compatibility, energy efficiency, and maintenance requirements to ensure optimal performance and longevity.

Investing in a high-quality dosing pump from a reputable manufacturer can provide long-term benefits, including reduced operational costs, enhanced reliability, and improved process consistency. By taking a comprehensive approach to dosing pump selection and considering all relevant factors, you can optimize resource use, enhance operational performance, and set your operations on the path to success.

In conclusion, maximizing efficiency in today’s industrial landscape requires careful consideration and informed decision-making. By following the guidelines and recommendations outlined in this ultimate guide, you can select the right dosing pump for your needs and ensure that every drop counts. Whether you’re managing a chemical plant, a water treatment facility, or a food processing operation, the right dosing pump can play a pivotal role in achieving your goals and driving success in your industry.

Leave A Comment