If you’ve ever wondered what is dosing pump, the answer is simple: it’s a highly specialized pump built not to move large volumes of liquid, but to deliver small amounts with extreme accuracy.

Instead of flooding a system with fluid, a dosing pump carefully injects precise doses into a stream, tank, or process line at a controlled rate. This precision is crucial in industries where small changes in chemical concentration can lead to problems.

What is A Dosing Pump?

A dosing pump is a highly specialized pump built not to move large volumes of liquid, but to deliver small amounts with extreme accuracy. It delivers a set amount of liquid into a fluid stream, tank, or process line.

However, its main job isn’t to move a lot of fluid. Instead, it ensures small amounts of liquid are added accurately and consistently at a set rate.

A dosing pump operates based on a repeated cycle of suction and discharge.

During suction, the pump draws liquid from a container or reservoir into its chamber. During discharge, the pump injects that liquid into the target system at a specific flow rate.

You can adjust the dosing rate manually or electronically, depending on the design. Many modern dosing pumps now have digital controllers and communication interfaces. This lets them connect with automated systems and allows for precise remote adjustments.

Dosing pumps are widely used in industries that require precise chemical treatment or controlled additives.

- In water and wastewater treatment, they inject chlorine, coagulants, or pH-adjusting agents. This helps keep the water safe and clean.

- In agriculture, they inject fertilizers or nutrients into irrigation lines. This precise method boosts plant growth effectively.

- In food, beverage, and pharmaceutical manufacturing, they add preservatives, flavorings, or active ingredients. They follow strict hygiene and dosage standards.

- In the oil, gas, and chemical sectors, they use inhibitors, catalysts, and other agents. These protect equipment and help processes run efficiently.

In short, a dosing pump is a specific type of pump used to measure liquids precisely. It offers controlled flow and reliable operation. This adaptability is vital in industries where even minor shifts in chemical concentration can result in inefficiencies, quality issues, or safety dangers.

What is The Difference Between Metering Pump and Dosing Pump?

People often toss the two terms around like they’re synonyms, but there’s a subtle difference in nuance.

A dosing pump is any pump that delivers a controlled quantity of liquid into a system. The key word is dose. You want to add just the right amount of chemical, medicine, or additive.

Dosing pumps vary in size and complexity. Some are small and simple, like solenoid-driven pumps for swimming pools. Others are larger and digital, such as stepper-motor pumps used in chemical plants. The focus is on introducing the substance into the system.

A metering pump, on the other hand, emphasizes measurement. It’s a type of dosing pump made to deliver liquid accurately and consistently.

A true metering pump lets the operator adjust the flow rate accurately, often to fractions of a milliliter per stroke. This ensures the flow remains consistent over time. “Metering” comes from the fact that the pump’s output can be calibrated and “metered” against a standard.

So you could think of it like this:

- All metering pumps are dosing pumps, but not all dosing pumps are metering pumps.

- A dosing pump is about adding a chemical into a process.

- A metering pump is about doing so with verifiable precision.

Industries often use “dosing pump” loosely, especially in water treatment and agriculture. In contrast, “metering pump” appears in stricter contexts, like pharmaceuticals, oil and gas, or laboratory processes.

It’s a bit like cooking at home versus in a lab kitchen. At home, you add salt to your soup with a spoon. In the lab, you measure exactly 2.00 grams using a calibrated scale.

The Main Types of Dosing Pumps

Here’s the overview of several types of dosing pump:

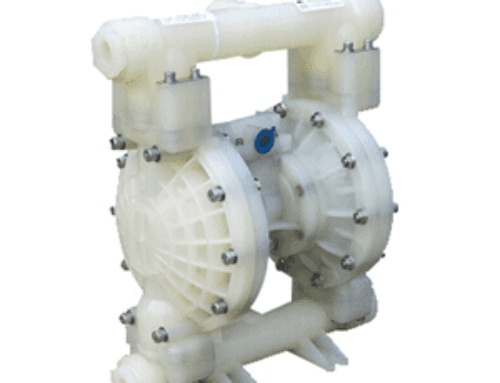

1. Diaphragm Dosing Pump

The diaphragm dosing pump is the most common and reliable design. Inside, there’s a flexible membrane that moves back and forth. When it pulls back, it sucks in liquid; when it pushes forward, it expels liquid.

This back-and-forth action gives you accurate, repeatable doses. The diaphragm can handle corrosive or dangerous chemicals. This is because the pumped fluid never contacts moving metal parts.

The main trade-off is that the flow comes in pulses, not a smooth stream. However, modern electronic controls can help with this. These pumps are vital in water treatment plants. They quietly add the right amount of chlorine or anti-scaling agents to your drinking water.

2. Piston Dosing Pump

The piston or plunger dosing pump works in a similar way, but instead of a flexible diaphragm, it uses a rigid piston that physically pushes the liquid out. You can think of it like a miniature engine piston that compresses liquid instead of air and fuel. This design enables the pump to produce high pressures. As a result, it works very precisely in challenging environments.

The catch is that the piston touches the liquid directly. If the fluid is corrosive, abrasive, or chemically aggressive, the seals wear out fast. This leads to maintenance issues. Still, when you need to inject chemicals into oil pipelines or handle very high-pressure processes, piston pumps are unmatched.

3. Peristaltic Dosing Pump

The peristaltic dosing pump is a gentler creature. Imagine squeezing toothpaste out of its tube—that’s essentially what it does. A set of rollers compresses a flexible tube, pushing the liquid along inside.

Only the inside of the tube touches the fluid. This makes it perfect for situations where hygiene and contamination control matter. Thus, it’s common in the food industry for adding flavors and colors. It’s also used in labs and pharmaceutical production, where cleanliness is important.

The downside is that the tubing wears out over time. It also can’t handle very high pressures. But for precise, low-pressure, clean dosing, it’s perfect.

4. Solenoid Dosing Pump

The solenoid dosing pump takes a different approach. Instead of relying on a motor, it uses an electromagnet to move a small diaphragm.

Every pulse of the solenoid pulls and pushes, metering out an exact dose. This design is compact, energy-efficient, and very accurate for low-flow applications. Thus, a solenoid pump likely adds small amounts of chlorine in swimming pool setups.

The limitation is scale. It’s not ideal for very high pressures or large flow rates. However, when you need something precise, affordable, and compact, it works well.

5. Motor Driven Dosing Pump

Finally, the stepper-motor driven dosing pump represents the modern “smart” generation. It uses a stepper motor instead of simple pulsing.

This motor can be digitally controlled to move in small steps. This lets the pump generate a smooth, steady flow. It removes the pulsing issue found in traditional diaphragm pumps. You can also program it or connect it to control systems using signals like 4–20 mA or RS485. This way, the pump integrates into a larger automated process.

These pumps are used in advanced industries like oil and gas plants, chemical factories, and high-tech farms. They offer precision, flexibility, and work well with digital monitoring systems. The trade-off is that they’re more expensive and require a bit more sophistication to set up, but they deliver accuracy down to the drop.

Now, you know exactly what is a dosing pump and what its types are. If you need this kind of pump, you can always get one at WRS. We have all kinds of dosing pumps for home or industrial needs. Contact us to talk about your requirements.

Leave A Comment