In industrial operations where accuracy and reliability are non-negotiable, smart dosing pumps are practically the best for keeping operations smooth and cost-effective.

But what exactly makes a dosing pump smart? In this post, we explore how our Eignal Series EMG Model by WRS sets the standard through advanced digital features tailored for modern industrial usage.

What is Eignal Series EMG Model?

The Eignal Series EMG Model is a stepper motor-driven mechanical diaphragm metering pump, engineered to handle both corrosive and non-corrosive liquids with viscosities ranging from 0.3 to 1000 cps.

Its rated flow ranges between 15 to 150 liters per hour, with pressures from 10 to 4 bar. Therefore, it is ideal for a wide spectrum of applications including water treatment, chemical processing, food and beverage dosing, and agriculture.

The EMG model is built with high-grade materials to ensure long-term performance. For the pump head, users can choose between PVDF or SS316, both known for their chemical resistance. It also features a five-layer diaphragm that enhances durability during continuous operation.

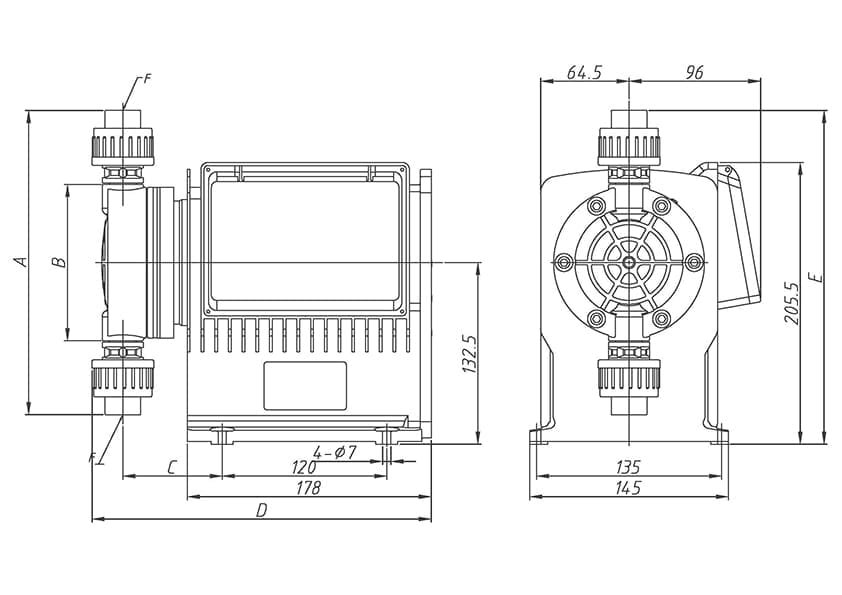

The EMG has a compact design that saves space in tight installations. It offers steady-state accuracy of ±1%, so dosing stays accurate and consistent. Plus, its low energy consumption makes it both cost-effective and environmentally friendly. These qualities offer a solution for operators who need consistency without added complexity.

However, what truly sets the Eignal Series EMG model apart is its smart digital capabilities. We’ve designed the pump to be able to adapt, respond, and integrate seamlessly into modern industrial systems.

What Makes the Eignal Series EMG Model Smart?

The EMG is built to think with you. It offers a range of intelligent features that go beyond basic mechanical dosing. These features allow it to connect, respond, and adjust automatically to your process. That’s what makes it especially useful for complex systems where timing and adaptability matter most.

So, what exactly are these features that make the EMG a smart dosing pump?

1. RS485 Communication: Seamless System Integration

One of the hallmarks of a smart pump is its ability to communicate effectively within a system. The EMG features RS485 communication. This protocol is widely used in industrial environments because it’s stable and reliable.

It also supports long-distance data transmission, which is useful when the pump needs to be part of a larger automated system. This allows integration into SCADA systems, PLCs, or other automation frameworks.

Various industries, including chemical plants and water treatment facilities, can utilize our EMG pump in real time. Meaning, users can monitor, configure, and trigger the smart dosing pump almost instantly, even remotely. Thus, operations become more efficient and responsive.

2. 4–20mA Analog Input: Analog Precision for Digital Control

The 4–20mA control input is another vital feature. This analog signal is widely used in process control. It lets external devices such as flow meters, pH sensors, or PLCs send clear and specific instructions to the dosing pump.

With this, operators can adjust the pump flow rate dynamically based on real-time input from their system. This helps keep dosing consistent and reduces unnecessary waste. For instance, a pH correction application can instantly alter dosing levels to maintain balance without human intervention.

3. Pulse Signal Control: Synchronizing Doses with External Devices

The Eignal Series EMG also supports pulse signal control. This feature is important when dosing needs to happen at steady intervals or in coordination with other systems. For example, it can work alongside water meters or production lines to ensure timing stays accurate.

Every pulse received can represent a predefined volume of fluid to be dosed. This feature is especially useful in batching operations or where proportional dosing is required. This helps maintain high accuracy and keeps every part of the process in sync.

4. Full Touch Screen Display: Human-Machine Interface Made Simple

Ease of operation is often overlooked. Yet, it plays a major role in minimizing downtime and errors. The EMG addresses this with a full touch screen interface that provides real-time feedback and intuitive navigation.

Operators can monitor flow rates, alarms, and settings without navigating a maze of buttons. The interface also allows for digital flow adjustment from 0% to 100%, regardless of whether the pump is running.

Smart Dosing for Smart Industries

The Eignal Series EMG Model offers a variety of smart features. It includes automated alarms for high or low pressure and liquid levels. It also supports timer-based and volume-based dosing functions. These features give operators better control over dosing. They also provide real-time feedback and make the entire system more responsive.

In many dosing systems, operators struggle with inconsistent output, time-consuming manual recalibration, and difficulty connecting with automation tools. These challenges can lead to inefficiencies, wasted resources, and production delays.

That’s why the smart features in the EMG matter. They help solve these issues through better accuracy, built-in communication options, and responsive control.

So, is a smart dosing pump necessary? In many industries, the answer is yes. A smart dosing pump actively improves your workflow. It can talk to other systems, adjust itself on the fly, and give you feedback you can act on. This means fewer errors, less downtime, and smoother operations. Choosing Eignal Series EMG Models means getting a smart dosing pump that improves efficiency, connects easily with your systems, and grows with your operation.

Leave A Comment