Solenoid Driven Dosing PumpSolenoid Driven Dosing PumpSolenoid Driven Dosing Pump – Eignal Series – EML Models

SMART SOLENOID DRIVEN DOSING PUMP

EML dosing pump is a new version of microprocessor controlled solenoid diaphragm pump with changeable frequency. Is has all the features of the MLS models, with additional Modbus 485 control, and more advanced display screen. WRS is consistently investing for upgrading our pumps to meet the current market requirements and the changing needs of our valued customers. As the industry is moving to more automated system ‘The Eignal Series’ is your best choice when looking for robust durable and productive metering pumps.

Your new smart solenoid metering pump EML by WRS has rated flow range of 1 ~ 20 l / h, with corresponding maximum output pressure of 10 ~ 1bar. The pump outlet displacement can be adjusted according to the pulse frequency selection switch. It is a simple structure, low energy consumption, accurate measurement, with a new screen display of electromagnetic diaphragm metering pump.

FEATURES

GENERAL SPECIFICATIONS

| Model | EML |

| Flowrate | 1 ~ 20 LPH |

| Pressure | 1 ~ 10 Bar |

| Pump Head Material | Standard: PVC Optional:PVDF, SS316 |

| Operating Method | Continuous or Intermediate |

| Number of pump head | 1 |

| Connection Type | ɸ5×8 Hose Compression Fitting |

| Flow Adjustment Method | Frequency Adjustment |

| Flow Adjustment Display Method | Digital Display |

| Control remotely | NO |

| Negative Suction | 2m |

| Inlet/Outlet Valve type | Double Ball Valve |

| Protection | IP65 |

| Insulation Class | F |

| Accuracy | ±2% in stable condition |

| Weight | Gross: 3.2 KG

Net: 4.2 KG |

| Driving method | Internal Solenoid Drive |

| Input Power | 28W |

| Supply Required | 1Ph 240V 50Hz / 1PH 110V 60Hz |

| Stroke per Minute | 80 ~ 180 |

DIAPHRAGM

| Diameter | 60 ~84 mm |

| Material | 1st Layer: PTFE 2nd Layer: EPDM Rubber 3rd Layer: 3.0mm SUS304 4th Layer: Nylon Fibber 5th Layer: EPDM Rubber |

FLUID PARAMETERS

| Fluid temperature range | -15℃~60℃ |

| Viscosity range | 0.3~1000cps |

ENVIRONMENT PARAMETERS

| Environment temperature range | -10℃ ~ +45℃ |

| Outdoor Installation | Yes, with shelter protection from rain and direct sunlight. |

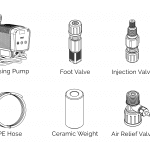

STANDARD FACTORY EXPORT SET

MODEL SELECTION

| Model | Flow (lph) | Pressure (bar) | Stroke/min | Diaphragm Dia (mm) | Weight (kg) |

|---|---|---|---|---|---|

| EML0001 | 1 | 10 | 80 | 34 | 3.2 |

| EML0002 | 2 | 10 | 140 | ||

| EML0004 | 4 | 8 | 180 | ||

| EML0005 | 5 | 5 | 140 | 41 | |

| EML0008 | 8 | 4 | 170 | ||

| EML0010 | 10 | 3 | 130 | 51 | 4.2 |

| EML0012 | 12 | 2 | 150 | ||

| EML0015 | 15 | 2 | 160 | ||

| EML0020 | 20 | 1.5 | 180 |

MATERIAL SELECTION

| Pump Head Material | Diaphragm | Valve Seat | Valve Ball | Inlet | Outlet |

|---|---|---|---|---|---|

| PVC | PTFE | Viton Rubber | Ceramic | PE | PE |

| PVDF | PTFE | Viton Rubber | Ceramic | PE | PE |

| SS304 | PTFE | SS304 | SS304 | SS304 | SS304 |

| SS316 | PTFE | SS316 | SS316 | SS316 | SS316 |

*For chemical compatibility table, please visit here.

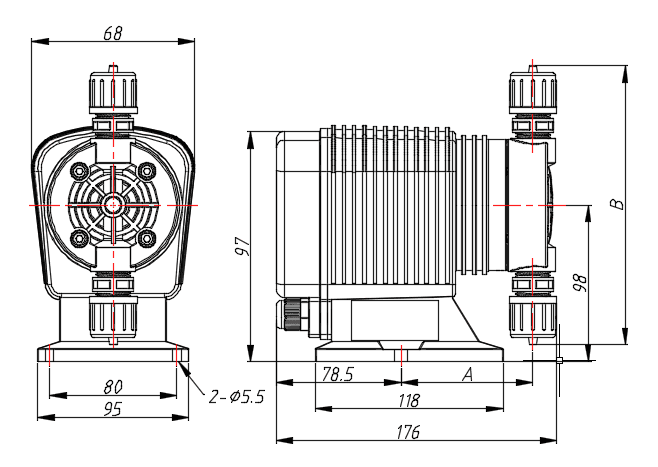

DIMENSION (mm)

| Model | Pump Head Material | Connection | A | B |

|---|---|---|---|---|

| EML0001 – EML0020 | PVC | Φ5×8 PE Hose Compression Fitting | 18 | 175 |

| PVDF | ||||

| SS316 | 17 | 158 |