ML SERIES

SOLENOID DRIVEN DOSING PUMP

ML metering pump is a microprocessor controlled solenoid diaphragm pump with changeable frequency. It is capable for all kinds of solutions dosing, including corrosive solutions. It is widely used in petroleum, chemical, food, pharmaceutical, paper, light industry, agriculture, water conservancy and other industrial and technological sectors, in the process solution metering and dosing. Solenoid metering pump is the use of electromagnetic push rod driven diaphragm in the pump head reciprocating movement, causing the pump head chamber volume and pressure changes. Changes in pressure caused by suction 4 valve and discharge valve opening and closing, to achieve quantitative liquid suction and discharge. ML solenoid metering pump rated flow range is 1 ~ 20 l / h, with corresponding maximum output pressure of 10 ~ 1bar. The pump outlet displacement can be adjusted according to the pulse frequency selection switch. It is a simple structure, low energy consumption, accurate measurement, with a new screen display of electromagnetic diaphragm metering pump.

What is the difference with MLS Series?

The main difference between ML and MLS Series is the option to control remotely. The MLS Series has an additional signal connection for 4-20mA signal or pulse connection. While ML Series does not have this option. Other than that, all parameters perform the same.

FEATURES

GENERAL SPECIFICATIONS

| Model | ML Series |

| Flowrate | 1 ~ 20 LPH |

| Pressure | 1 ~ 10 Bar |

| Pump Head Material | Standard: PVC Optional:PVDF, SS304, SS316 |

| Operating Method | Continuous or Intermediate |

| Number of pump head | 1 |

| Connection Type | ɸ5×8 Hose Compression Fitting |

| Flow Adjustment Method | Frequency Adjustment |

| Flow Adjustment Display Method | Digital Display |

| Control remotely | NO |

| Negative Suction | 2m |

| Inlet/Outlet Valve type | Double Ball Valve |

| Protection | IP65 |

| Insulation Class | F |

| Accuracy | ±2% in stable condition |

| Weight | Gross: 3.2 KG

Net: 4.2 KG |

| Driving method | Internal Solenoid Drive |

| Input Power | 28W |

| Supply Required | 1Ph 240V 50Hz / 1PH 110V 60Hz |

| Stroke per Minute | 80 ~ 180 |

DIAPHRAGM

| Diameter | 60 ~84 mm |

| Material | 1st Layer: PTFE 2nd Layer: EPDM Rubber 3rd Layer: 3.0mm SUS304 4th Layer: Nylon Fibber 5th Layer: EPDM Rubber |

FLUID PARAMETERS

| Fluid temperature range | -15℃~60℃ |

| Viscosity range | 0.3~1000cps |

ENVIRONMENT PARAMETERS

| Environment temperature range | -10℃ ~ +45℃ |

| Outdoor Installation | Yes, with shelter protection from rain and direct sunlight. |

STANDARD FACTORY EXPORT SET

In a standard packing of ML/MLS series solenoid dosing pump, you should have all items as shown below in the box. If there is any item is missing or damaged, please contact your shipping company or simply contact our friendly team.

PRODUCT IMAGE

Three Button Control

PVC , Stainless Steel, PVDF

ML Series (top) MLS Series (Bottom)

MODEL SELECTION

| Model | Flow (lph) | Pressure (bar) | Stroke/min | Diaphragm Dia (mm) | Weight (kg) |

|---|---|---|---|---|---|

| ML0001 | 1 | 10 | 80 | 34 | 3.2 |

| ML0002 | 2 | 10 | 140 | ||

| ML0004 | 4 | 8 | 180 | ||

| ML0005 | 5 | 5 | 140 | 41 | |

| ML0008 | 8 | 4 | 170 | ||

| ML0010 | 10 | 3 | 130 | 51 | 4.2 |

| ML0012 | 12 | 2 | 150 | ||

| ML0015 | 15 | 2 | 160 | ||

| ML0020 | 20 | 1.5 | 180 |

MATERIAL SELECTION

| Pump Head Material | Diaphragm | Valve Seat | Valve Ball | Inlet | Outlet |

|---|---|---|---|---|---|

| PVC | PTFE | Viton Rubber | Ceramic | PE | PE |

| PVDF | PTFE | Viton Rubber | Ceramic | PE | PE |

| SS304 | PTFE | SS304 | SS304 | SS304 | SS304 |

| SS316 | PTFE | SS316 | SS316 | SS316 | SS316 |

*For chemical compatibility table, please visit here.

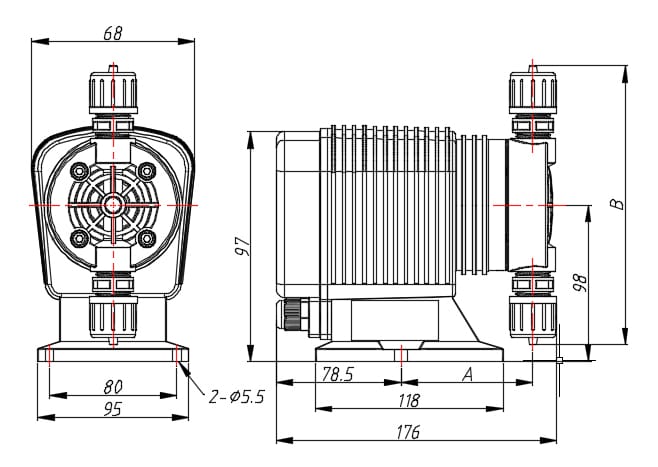

DIMENSION (mm)

| Model | Pump Head Material | Connection | A | B |

|---|---|---|---|---|

| ML0001 – ML0020 | PVC | Φ5×8 PE Hose Compression Fitting | 18 | 175 |

| PVDF | ||||

| 304/316 | 17 | 158 |